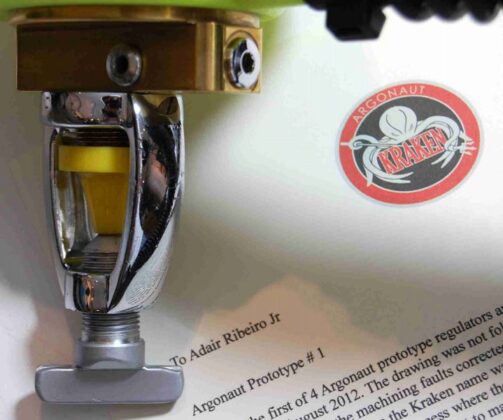

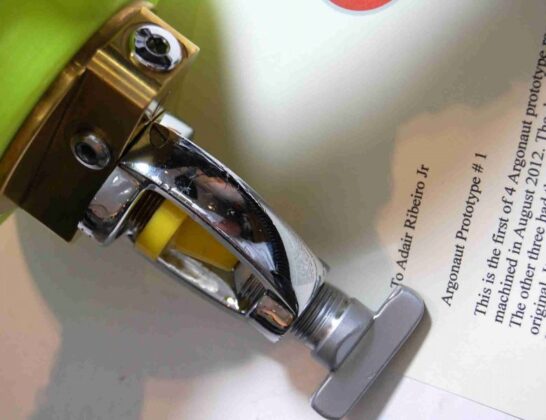

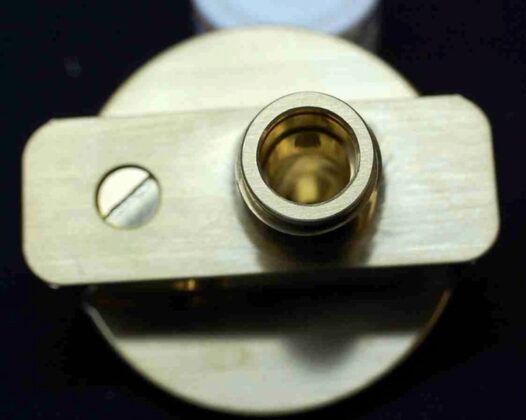

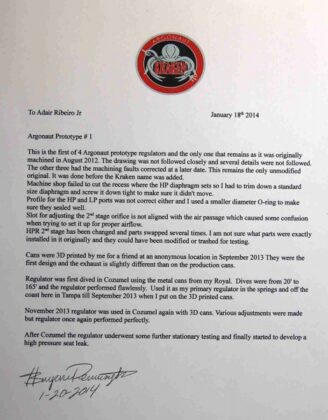

This is the first of 4 Argonaut prototype regulators and the only one that remains as it was originally machined in August 2012. The drawing was not followed closely and several details were not followed. The other three had the machining faults corrected at a later date. This remains the only unmodified original. It was done before the Kraken name was added.

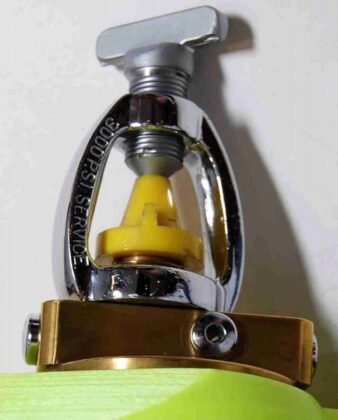

Machine shop failed to cut the recess where the HP diaphragm sets so I had to trim down a standard size diaphragm and screw it down tight to make sure it didn’t move.

Profile for the HP and LP ports was not correct either and I used a smaller diameter O-ring to make sure they sealed well.

Slot for adjusting the 2nd stage orifice is not aligned with the air passage which caused some confusion when trying to set it up for proper airflow.

HPR 2nd stage has been changed and parts swapped several times. I am not sure what parts were exactly installed in it originally and they could have been modified or trashed for testing.

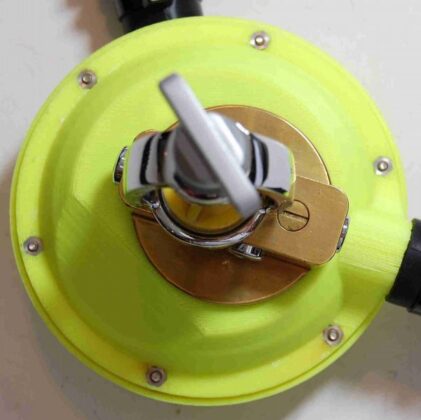

Cans were 3D printed by me for a friend at an anonymous location in September 2013 They were the first design and the exhaust is slightly different than on the production cans.

Regulator was first dived in Cozumel using the metal cans from my Royal. Dives were from 20′ to 165′ and the regulator performed flawlessly. Used it as my primary regulator in the springs and off the coast here in Tampa till September 2013 when I put on the 3D printed cans.

November 2013 regulator was used in Cozumel again with 3D cans. Various adjustments were made but regulator once again performed perfectly.

After Cozumel the regulator underwent some further stationary testing and finally started to develop a high pressure seat leak.”

By Bryan Pennington – Vintage Double Hose VDH Worldwide