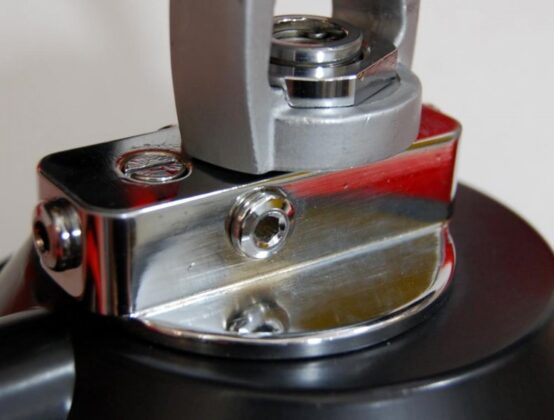

This is one of 7 prototypes made by a machine shop in San Jose California. All 7 had problems with the port hole sizing and and with the concentric alignment of the bore for the 2nd stage volcano orifice.

Slot cut in the 2nd stage volcano orifice is not correctly aligned with the orifice leading to the 2nd stage so the visual reference point it was supposed to reference showing complete flow though the orifice is not correct. Body also shows machine and tooling marks that were not removed before chrome plating.

After some additional machine work 5 of the prototypes were made useable and were put out for underwater testing.

Bryan used this regulator for long term testing of the high pressure seat and volcano orifice and over the course of testing it was cycled on the quick set bench fixture for over 10000 cycles with no failure of the high pressure seat or volcano orifice.

Regulator still has the original nylon tabs to hold the 2nd stage in place and the lever has been tried at various bend angles in an attempt to maximize response.

Regulator cans are on of 6 pre production samples sent for testing. Originally the mold ejector pins on the exhaust side can were placed around the perimeter of the exhaust valve and left small raised circles that needed to be sanded smooth for the valves to seat properly. Pins were relocated on production cans to prevent this problem.

During testing in Cozumel Herman said “Wonder what it would look like with red hoses?” So Bryan asked the hose manufacture to make a few sample hoses in a specific red color to match the Kraken logo color. The sample hoses were a lighter durometer than normally produced and were made more for display and analysis than diving use. This is the first regulator they were seen on and Bryan used it in pictures to solicit feedback from the double hose community.