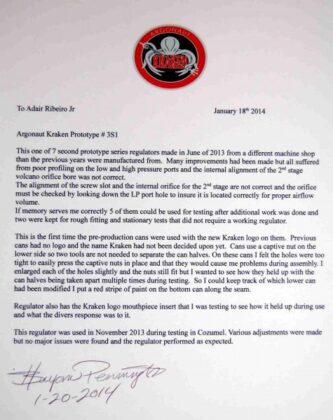

This is one of the 7 regulators of the second prototype serie made in June of 2013 from a different machine shop than the previous years were manufactured from. Many improvements had been made but all suffered from poor profiling on the low and high pressure ports and the internal alignment of the 2nd stage volcano orifice bore was not correct.

The alignment of the screw slot and the internal orifice for the 2nd stage are not correct and the orifice must be checked by looking down the LP port hole to insure it is located correctly for proper airflow volume.

About 5 of them could be used for testing after additional work was done and two were kept for rough fitting and stationary tests tha did not require a working regulator.

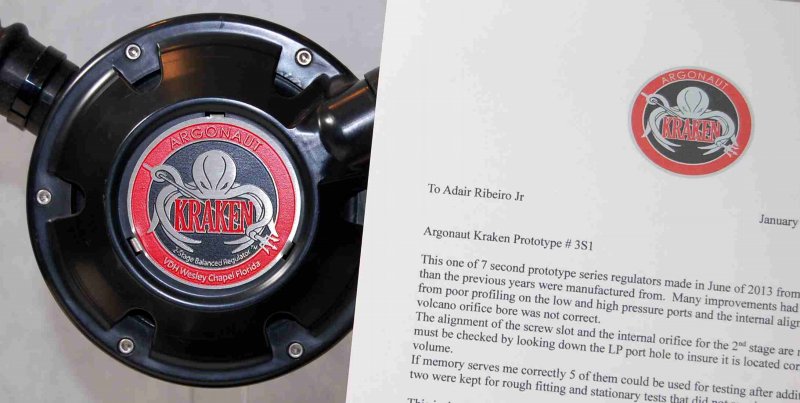

This is the first time the pre-production cans were used with the new Kraken logo on them. Previous cans had no logo and the name Kragen had not been decided upon yet. Cans use a captive nut on the lower side so two tools are not needed to separate the can halves. On these cans, the holes were too tight to easily press the captive nuts in place and that they would cause problems during assembly. So the holes were enlarged slightly and the nuts still fit but Bryan wanted to see how they held up with the can halves being taken apart multiple times during testing. Bryan could keep track of wich lower can had been modified he put a red stripe of paint on the bottom can along the seam.

Regulator also has the Kraken logo mouthpiece insert tha Bryan was testing to see how it held up during use and what the divers response was to it.

This regulator was used in November 2013 during testing in Cozumel. Various adjustments were made but no major issues were found and the regulator performed as expected.